Product overview

The Olga™ dynamic multiphase flow simulator models transient flow (time-dependent behaviors) to maximize production potential. Transient modeling is an essential component for feasibility studies and field development design. Dynamic simulation is essential in deep water and is used extensively in both offshore and onshore developments to investigate transient behavior in pipelines and wellbores. Transient simulation with the Olga simulator provides an added dimension to steady-state analysis by predicting system dynamics, such as time-varying changes in flow rates, fluid compositions, temperature, solids deposition, and operational changes.

From wellbore dynamics for any well completion to pipeline systems with various types of process equipment, the Olga simulator provides an accurate prediction of key operational conditions involving transient flow.

Release updates

As part of our ongoing commitment to excellence, we continuously strive to enhance our product. This latest version brings multiple improvements, updates, and bug-fixes. The most important improvements are mentioned below. Please read the release notes for the full overview.

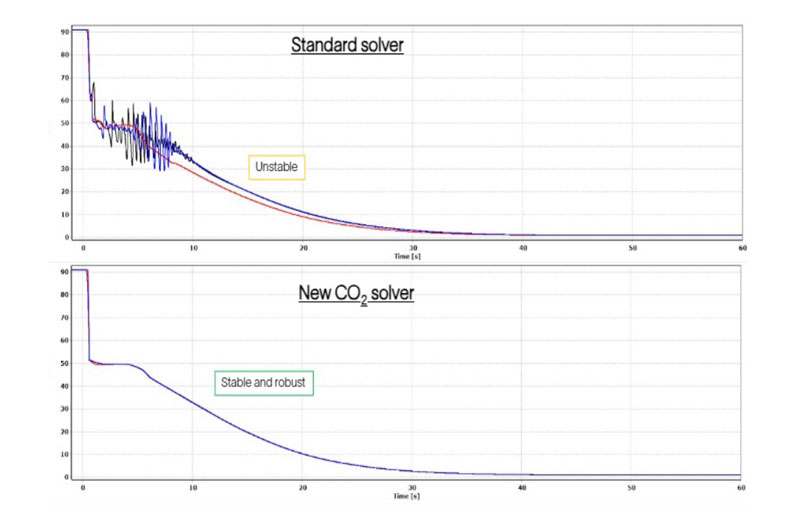

Olga simulator‘s new solver for CCS

Olga 2025.1 features a newly developed solver for CCS, created through the joint industry project (JIP) Olga CO2. Reach aimed at enhancing CO2 handling capabilities. This solver is designed to provide robust and accurate simulations of CO2 transport and injection. This is crucial for the successful design and operation of CCS systems. It enables reliable and precise multiphase modeling with strong vaporization and condensation. This is key for CCS transport systems and will lead to optimal capital and operational costs.

The Olga simulator’s new solver for CCS offers several improvements, including increased implicitness between pressure and energy, and a reformulation of flash calculations to enhance numerical stability. It ensures numerical stability and reliable solutions, providing increased accuracy without compromising simulation speed.

Research and development of the Olga simulator's new solver received funding from the CLIMIT program (climit.no) under grant no. 621254 (Olga CO2 Reach).

PVTsim Compositional Tracking Engine

In Olga 2025.1, we re-introduced PVTsim from Calsep as an option for running compositional tracking simulations. Calsep is a leading provider of PVT simulation services to the oil and gas industry, which has solved PVT modeling projects in all continents. The projects involve EoS modeling of all types of reservoir fluids, including natural gas, gas condensates, near critical fluids, black oils and heavy oils. PVTsim CompTrack engine is currently available for PT flash only.

Major update to Olga Slug Tracking

In Olga 2025.1, we have enhanced Olga Slug Tracking by introducing a new option to “track” the development and propagation of statistical mean slug properties. This new model, referred to as “mean tracking,” contrasts with the conventional “individual tracking” model, which tracks the properties of each individual slug.

![]()

The MEAN tracking model offers several advantages, including generally faster simulation speeds and a reduced need for long simulations to produce a statistically meaningful number of slugs. However, because it does not resolve individual slug properties, mean tracking cannot provide distributions of slug properties, such as slug length. The speed-up benefits of mean tracking are particularly significant in systems with extensive hydrodynamic slugging.

The MEAN tracking development received funding from the PETROMAKS 2 program of the Research Council of Norway as project no. 317814 and further industrial support through Olga Verification and Improvement Projects (OVIP).

The MEAN tracking option requires no post processing for extracting average variables.

Flow model improvement

In Olga 2025.1, we improved the Olga HD stratified flow model by introducing new turbulence closures at the interfaces between immiscible fluid layers. The new HD model exhibits superior accuracy particularly in gravity dominated gas-condensates systems (low flowrates), while maintaining similar performance to the old model in other situations. The new HD model's capability has been verified against several gas-condensates pipelines operational data equipped with high quality measurements. The new model does not affect non-stratified flow model although it conceivably alters the flow regime transition (which is based on minimum slip).

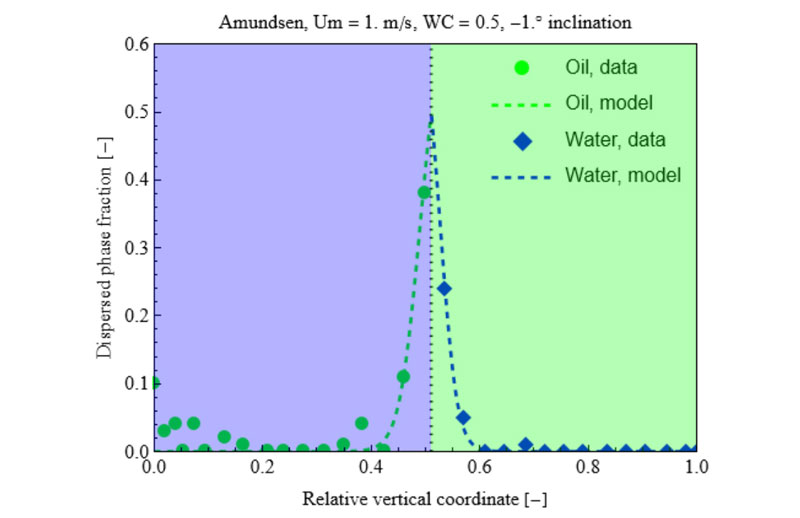

We introduced a new oil-water dispersion model for Olga HD in 2025.1 release. The model simulates dispersion concentration profiles in each cross-section of the pipe, enabling predictive modeling of oil-water flow regime, presence/absence of continuous phase layers and improving results for wall shear stress, which are key characteristics for assessment of corrosion risk in pipelines. The oil-water dispersion model has been validated against experimental measurements of oil and water distribution and tuned for the best performance against two-phase oil-water and three-phase field and laboratory data together with the updated Olga HD turbulence closures.

The development of new oil-water dispersion received funding from the PETROMAKS 2 program of the Research Council of Norway as project no. 317814 and further industrial support through Olga Verification and Improvement Projects (OVIP).

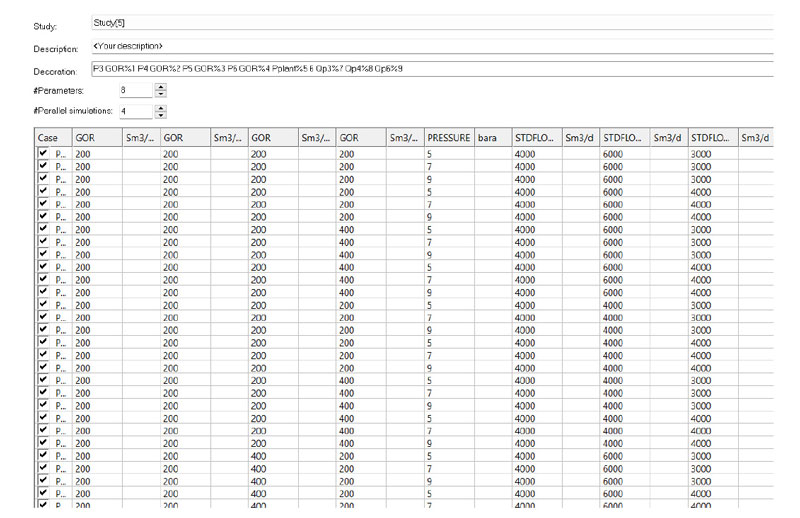

Run parametric studies in cloud

Olga 2025.1 introduces the important update to the parametric study functionality; the possibility of running parametric studies in the cloud. This way the user can utilize indefinite computer power in the cloud for parametric studies.

Update of Multiflash library

The KBC Multiflash® library has been updated from the previous release from 7.4. to 7.5.

In this version, a new set of tools has been added to assist with modeling fluids for carbon capture and storage (CCS) applications. A new tab includes shortcuts to help users decide which models to use, such as CPA (Cubic-Plus-Association), CPA with hydrates, CPA with EOS-CG (Equation of State for Combustion Gases) for volume properties, and EOS-CG. A new viscosity model, the Lennard-Jones viscosity model, has been developed to improve viscosity predictions for CO2-rich fluids and can only be used from this tab. Additionally, a new model for the density of salt aqueous solutions is used in the creation of tables.

For CO2component, updated temperature-dependent correlations improve accuracy, including saturation pressure, saturated liquid density, and ideal gas heat capacity. For mercury component, some temperature-dependent properties have been updated, including saturation pressure and liquid density.

Tables in the Olga simulator do not report errors when those errors are not significant, such as failures in the surface tension model in the single-phase region. When using Multiflash 7.5 in Olga Compositional Tracking module, the new model for the density of aqueous solutions is used if salts are present.

In addition to these improvements, the Olga 2025.1 release contains several other enhancements and minor bug fixes.

Users

The product is suitable for use by production, process, and flow assurance engineers, and those involved in multiphase flow simulation.